WATERMASTER CLASSIC III – is a combination of backhoe and suction dredger

All the work at a site with one machine

Most environmental dredging sites require different kind of works. When using traditional methods several different vessels and support machines are needed to complete the job. That makes these solutions uneconomical compared to Watermaster which can by itself complete most jobs at the site. A versatile machine saves money in both operational and investment costs.

Backhoe work

The base machine has a 400 l backhoe bucket with teeth as standard. For soft soil a 700 l bucket is also available. There are also special purpose buckets available. The most popular is the rake which is developed for large-scale mechanical removal of vegetation. The rake is also suitable for cleaning up the bottom from trash before suction dredging. Deepening rivers, canals, lakes, shorelines, marinas and wet lands, opening up new water canals, constructing break-waters etc. are typical Watermaster backhoe applications. The backhoe is also used to complete and finalize suction dredging sites by instance landscaping the water front after suction work or by sinking large stones deeper in the bottom.

Suction dredging

For such dredging Watermaster has two alternative tools available; the cutter pump and the bucket pump. They both use submersible pumps. Thus they are immediately operational, when the pump is lowered below the water level. The cutter pump has a higher capacity and higher wear resistance. It also creates higher pressure (4 bar) and allows a longer discharge distance (up to about 1.5 km without booster pumps). The cutter pump is suitable for sand, silt, sludge, mud and other organic materials. The material may contain also some bigger grains up to 50 mm in diameter.

The pump bucket can handle soils with roots, reeds and other vegetation, and it is commonly used in environmental dredging projects. It has horizontal and vertical cutters, which break the vegetation before the pump inlet.

Independent dredging movement

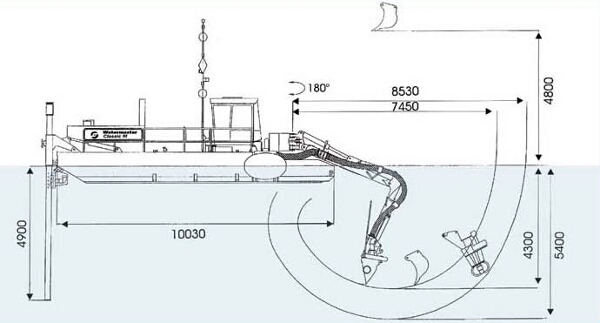

Watermaster’s independent dredging movement is based on 2 hydraulic stabilizers and hydraulic excavator. During dredging work Watermaster’s body is kept steadily in place by pushing 2 or 4 stabilizers against the bottom. After the body is solidly anchored with the stabilizers, the excavator moves the dredging tool in the bottom soil.

From one anchorage position Watermaster can handle a large area in length and width. For instance with the cutter pump the length of the work area is 4 m at water depth of 4.5 m. When the water depth is less than 2.5 m supporting both the front and the rear stabilizers against the bottom does the anchoring. In deeper water only the rear stabilizers are supported against the bottom and the front stabilizers with the floaters are kept level on the surface.

Watermaster, unlike conventional dredgers, does not use wires, anchors and hydraulic winches for dredging. This makes Watermaster ideal for rivers, canals, harbours etc. where conventional dredgers block other water traffic with wires going across the navigable path.

Watermaster has excellent mobilization both at the work site and also between work sites. In the water Watermaster cruises with its own hydraulic propulsion system. The propeller can be hydraulically turned for steering and hydraulically elevated in shallow water. Watermaster can also move and operate in shallower water than its own draft or even on dry ground. Watermaster can walk from the water onto dry ground, where it is loaded on to a truck. On the truck it is transportable on public roads to a new site.

When coming to a new site Watermaster walks from the truck to the waterfront. Thereafter the machine cruises to the working site and starts to work. Set-up time before work is minimal, and no time is lost for lifting the vessel with a crane, pulling the vessel with a tugboat and setting up work anchors and wires with a service boat.

Watermaster’s unique walking capability makes it the only machine which can efficiently operate in shallow waters, wetlands and other confined areas. The method of anchoring with the hydraulic spuds and submersible pumps make Watermaster’s dredging efficiency superior also in deeper waters.

Watermaster’s hydraulic excavator has two hydraulic circuits for accessories: one supplies 185 l/min up to 300 bar pressure and the other supplies up to 80 l/min up to 210 bar pressure. Flow and pressure in both circuits are controlled independently. Besides this it is possible to add several extra circuits. These extra circuits make Watermaster suitable for almost any accessories, which are developed for hydraulic excavators.

With Watermaster these accessories can be used from the waterside, which opens up totally new possibilities for water construction works.

Pile driving is a good example of work, where the Watermaster is very attractive. Piles are driven near the waterfront to prevent erosion and to improve thelandscape.

Watermaster can drive round woodpiles as well as steel sheet profiles. Watermaster Classic is primarily a suction and backhoe dredger. However, its good mobility, hydraulic stabilizers and versatility of tools make it also an effective general water construction machine. Watermaster does all the tasks at one site. Watermaster dredgers are manufactured at Lannen Engineering’s plant in Loimaa, Finland. The plant has the ISO 9001 quality certificate and ISO 14001 environmental certificate.

| Technical dimensions | |

| Max reach below water | |

| - with cutter pump | -5,4 m |

| - with pump bucket | -4,3 m |

| - with hoe bucket | -4,3 m |

| -front stabilizers | -3,5 m |

| - rear stabilizers | -4,9 m |

| Most efficient dredging depth | |

| - with cutter pump | 0,8 – 4 m |

| - with pump bucket | 0,3 – 4 m |

| - backhoe dredging | 0,0 – 4 m |

| Cutter pump nominal capacity with water | 500 m3/h |

| - max pumping distance (without booster) | 1500 m |

| - cutter head diameter | 500 mm |

| - recommended discharge line diameter | 200-250 mm |

| - transport width | 3,3 m |

| - operating weight | 19 tons |

Ideal applications for Watermaster:

- Suction and backhoe dredging in rivers, canals, harbours, lakes. Coastal waters and basins

- Dredging in areas, where there is water traffic

- Dredging in places where it is difficult or impossible to work with other machinery (wetlands, shallow waters, shore lines, industrial pools, under bridges, in tunnels etc.)

- Where a versatile dredger is needed, which can both bump and excavate

- Where it is not feasible to mobilize several one-purpose machines (cutter suction dredger, backhoe dredger, tugboat, assembly cranes)

- Where pile driving at the waterfront is needed

- Where reeds and other vegetation disturbs conventional dredgers

- Where reeds and vegetation has to be removed

- Environmental dredging projects

Русский

Русский English

English