|

Crane chassis

|

|

Model:

|

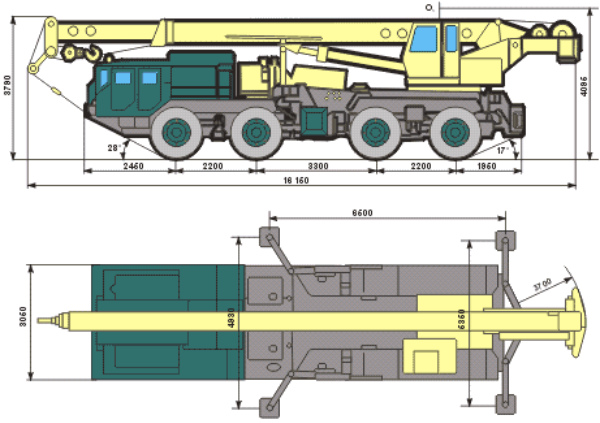

6571-100, retrofit wheeled MAZ-73131.

|

|

Type:

|

Off-road 8×8.

|

|

Chassis frame:

|

Riveted-welded, consists of two curved spars Z – shaped profiles-il, in which the length is welded to two amps – top and bottom.

|

|

Frame chassis:

|

Welded, box-section design.

|

|

Outriggers:

|

4 supports, X-shaped swivel. Lifting and lowering of supports – Hydraulic individual. Lift cylinders are equipped with attachment bracket bearings.

|

|

Engine:

|

Diesel 12-cylinder D-12A-525A liquid cooling. Power of 386 kW (525 hp.) at 2000 r / min. Maximum torque of 2208 kN at 1100-1400 r / min. Fuel tank – 280 x 2 l.

|

|

Transmission:

|

Torque converter – single-stage, with the transition to mode coupling and locking the pump and the turbine wheel. Transmission – planetary, 3 forward, 1 – back. control – through the mechanism of hydraulic spool type. Transfer case – two-speed three-shaft gearbox with central differential.

|

|

Bridges:

|

Leading with the central gear wheel and two planetary re-villas, the first two bridges – managed.

|

|

Suspension:

|

Independent, torsion bar, double wishbones.

|

|

Wheels and tires:

|

Single tires 1500 x 600 x 635, with a tread Prokhorov conductivity, pressure 0.387 MPa, with a centralized paging.

|

|

Steering:

|

The first and second axes with power.

|

|

Brakes:

|

All round shoe with automatic compensation for wear shoes clearance, control – air-hydraulic, dual circuit. The parking brake -belt acting on the bridges, mechanical.

|

|

Cab driver:

|

Two (left and right), double, two-door, closed type. Raising and lowering the outside doors have glass in a special frame. The seats are arranged one after the other. Cabins are equipped with heaters, ventilation hatches. In front of the cab mounted panel with instrumentation.

|

|

Electrical equipment:

|

24 VDC, 4 batteries, lighting in accordance with GOST 8769-75 “Outside lighting.”

|

|

Rotating platform

|

| Frame: |

Welded, boxed-girder construction. Slewing diameter of 1900 mm, single-row roller with internal teeth, provides rotation in both directions for an unlimited angle. |

| Hydraulic system: |

Dual circuit with remote hydraulic servo. Powered from the system of pump station power module, located on nonslewing part. Hydraulic pumps, axial piston and gear. Hydraulic axial piston for mechanisms. |

| The power module

(Diesel – pump

module): |

Diesel engine D-144-32 air-cooled and the pump drive diesel heater, muffler, oil tank – 350 l, hydro and electrical equipment module rated power 36.8 kW (50 hp.)., Torque 195 Nm (19.9 kg-m) @ 1800 r / min. |

| Boom: |

Double-acting hydraulic cylinder with check control valve. |

| Cargo winch |

With the driving force of 44.83 kN, with a two-stage helical gearbox built into the drum, normally closed disc brake, driven by two-speed axial piston motor. |

| Turning mechanism: |

Axial-rotary motor, two-stage planetary gearbox and disc brakes normally closed. |

| Operator’s cab: |

Steel sheet with a broad overview, with heating, with sound and heat insulation, with instrumentation. |

| Safeties: |

Electronic UCP, height limiter lifting hook suspensions, pressure rollers rope winches stops coiling rope winches automatic

brake winches attachment bracket, safety valves and brake valves. |

| Counterweight: |

Weighing 1.5 tons |

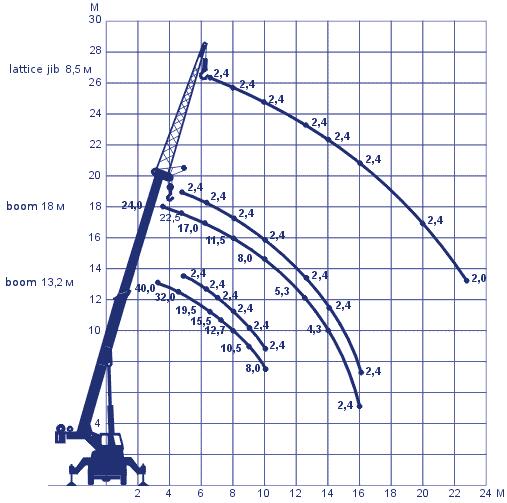

| Telescopic boom: |

Two-piece, Hydroficated, arm length of 13.2 to 18 m |

| Additional boom equipment: |

Lattice jib 8.5 m, is mounted on the longitudinal axis of the boom.

|

Русский

Русский English

English